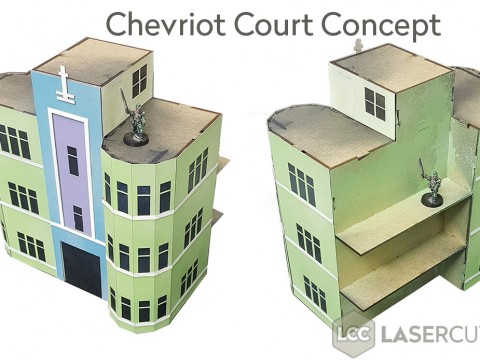

LCC and Scorched Earth Designs

Some news! I have entered into an agreement with Scorched Earth Designs (https://www.etsy.com/shop/ScorchedEarthStore) to produce LCC stuff in Australia. Contact them and let them know if there are specific items from the back catalog that they should carry (if they don’t already)! Happy modelling.